Modul GFS Production Planning and Control

Module GFS has fully featured manufacturing functions, which help to manage work-in-process activities and increase the productivity of manufacturing staff with labor-saving features that provide more control over production and scheduling.

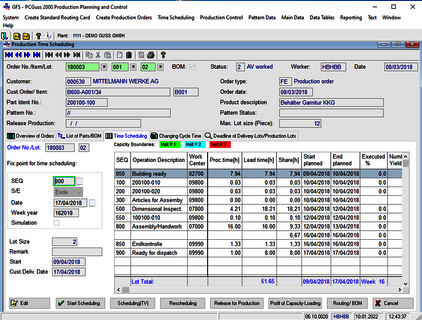

Quickly generate production orders from planned orders. Maximize manufacturing efficiency with, infinite and finite loading, forward and backward time scheduling.

Better manage labor and equipment capacity with powerful shop floor scheduling and explore scenarios to rapidly identify and resolve schedule conflicts and load issues.

Manufacturing and accounting data are completely integrated to help accurately track product costs

Overview of main functions :

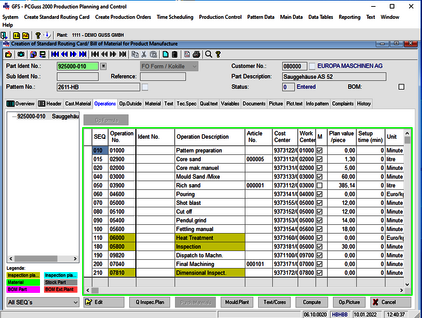

Specials in production process of foundries

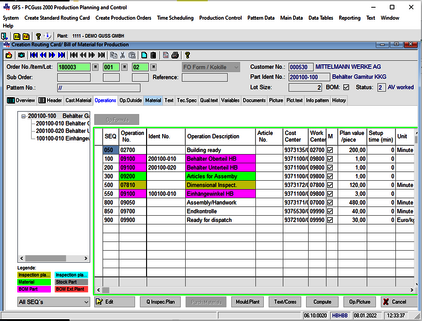

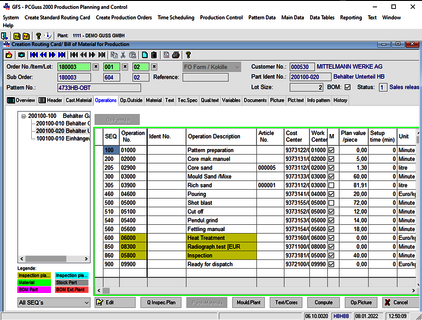

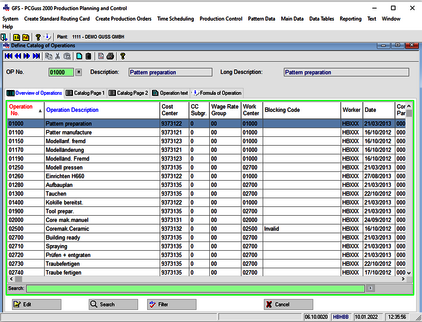

Supports all operations in patternshop

Provides production of cores

Uses moulding plants and supports hand moulding

Provides melting area

Supports all operations in fettling shop

Operates heat treatments

Operations for priming and painting

Specific quality controls for raw castings and for pre- and finish machining parts

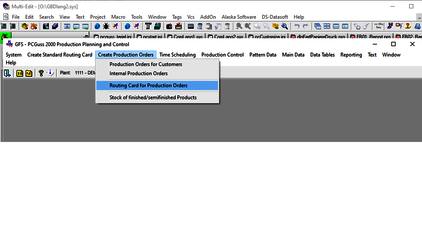

A production order has the following sequence of activities:

Order Creation, Scheduling, Availability Check, Capacity Requirements Planning, Order Release,

Shop Paper Printing, Material Withdrawal, Confirmations, Goods Receipt, Order Settlement